online message

The global push toward sustainability has made collaborative innovation between food producers and technology providers imperative. As climate challenges intensify, strategic alliances built on shared environmental objectives are becoming the cornerstone of progressive operational models. This article explores three critical dimensions for establishing impactful sustainability-focused partnerships: authentic collaboration, continuous improvement frameworks, and equipment longevity strategies.

Core Principles for Effective Partnerships

1. Authentic Collaboration

True sustainability partnerships require alignment beyond transactional relationships. Technology providers must deeply understand their clients' ecological targets, operational pain points, and long-term vision. Key practices include:

Goal Synchronization: Jointly defining sustainability KPIs during initial engagements.

Knowledge Exchange: Transparent sharing of environmental impact data and best practices.

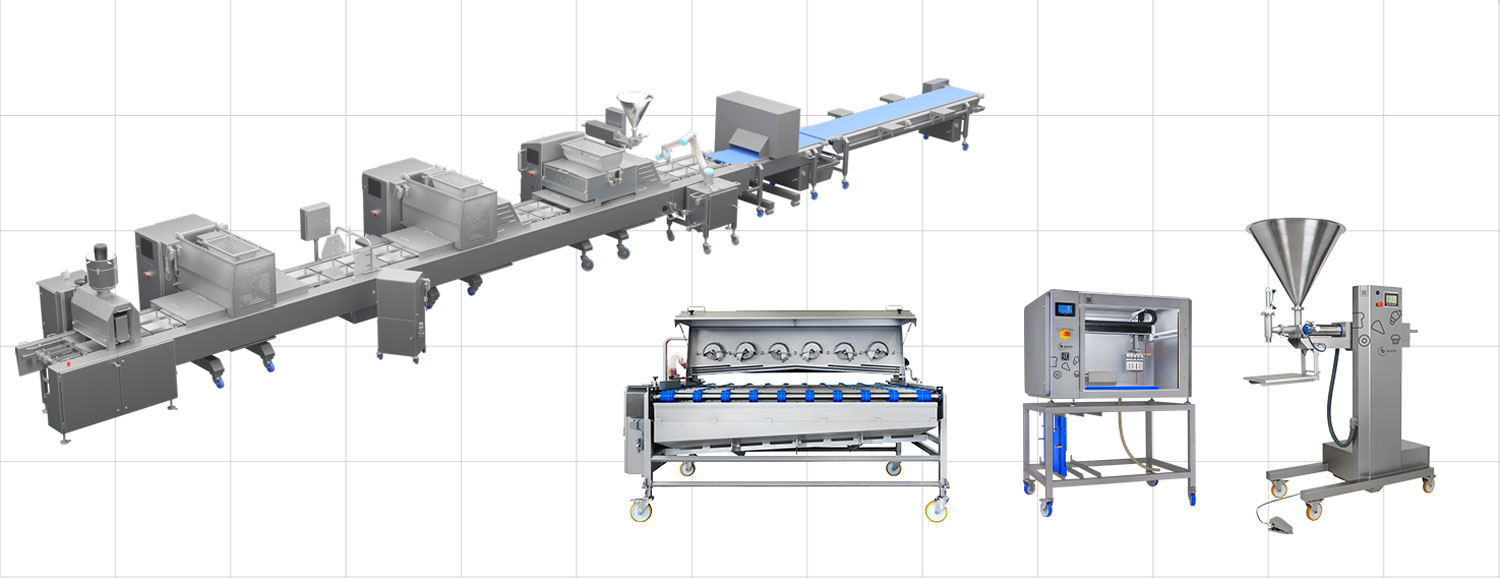

Solution Customization: Developing equipment and systems that address specific waste-reduction or energy-efficiency goals, such as yield-optimizing machinery or compostable packaging innovations.

2. Continuous Improvement Culture

Dynamic sustainability targets demand agile problem-solving. Forward-thinking technology partners should:

Conduct regular lifecycle assessments of deployed solutions.

Propose iterative upgrades to existing systems (e.g., retrofitting older machines with energy-saving components).

Embed environmental metrics into R&D pipelines for future products.

3. Designing for Longevity

Durable, adaptable equipment reduces resource depletion and supports circular economies. Priorities include:

Modular Design: Allowing components to be upgraded without full replacements.

Refurbishment Programs: Extending machinery lifespans through proactive maintenance and part replacements.

Material Circularity: Selecting recyclable materials and minimizing virgin resource dependency.

For food processors, selecting technology partners with ingrained sustainability values amplifies both ecological and economic returns. By prioritizing aligned visions, iterative innovation, and equipment resilience, the industry can transform supply chains into drivers of planetary health while maintaining competitive agility.